Model No: JEACE

Jeros JE ACE Industrial Washer

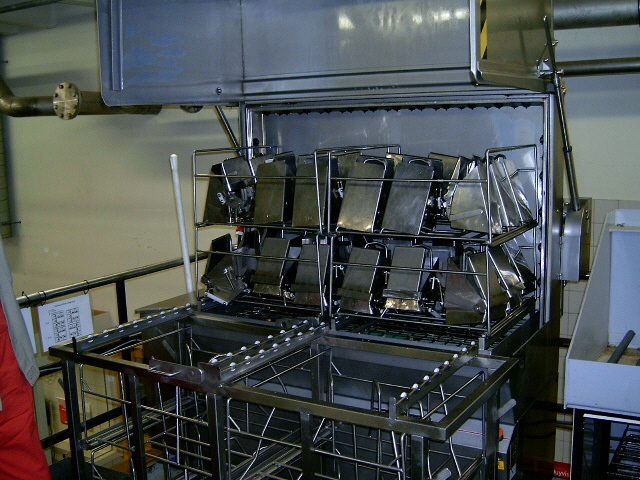

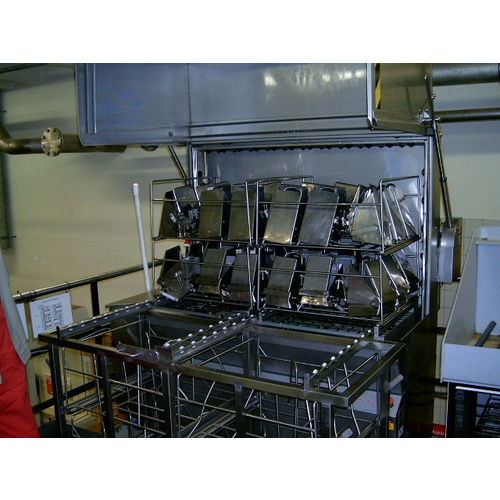

JEROS industrial washer. Perfect for food manufacturers and their weighing/packaging operations

The JEROS ACE industrial washer is the most flexible and efficient cleaning system for scale parts and weigh heads. This system saves substantial time. It speeds up production output by reducing the product change-over time, cutting labour costs, making washing easier, and achieving a perfect cleaning result.

The ACE system is a solution bearing in mind the increased hygiene regulations in the food industry.

Efficiency, optimum hygiene and safety form the core of the JEROS set of values.

They are the only manufacturer to have independent bacteriological tests carried out to measure the success of their cleaning systems. All products are tested by Eurofins Steins Laboratorie, a world recognised laboratory.

Due to the rinse temperature, of approx. 85ºC, Maximum Sanitisation is standard.

Winning Features

- Micro Processor controlled with waterproof keypad

- Easy one man operation

- Self cleaning program

- Adjustable wash temperature

- Adjustable wash time

- Mobile wash frame / trolley

- Automatic lid opening Automatic start when lid is closed

- Water and energy efficient

- 2 independent pumps (2 x 900 l/min) for low/high pressure

- Built-in drain pump

- Built-in end-rinse pump

- Prepared for automatic exhaustion (Ø 110 mm)

- Perfect wash system for the Ishida Multihead weigher or can be customised to suit your weigh head system brand

Hopper weigher component capacity With 2 or 3 litre weigh head hoppers, the ACE has a cleaning capacity of 32 fixed slots (or 48 for the 2 litre). This means that per 5min cycle, the hoppers of a 2 x16 component weigher are cleaned in one cycle! (or 3 x 16 for the 3 Litre)

The ACE system includes trolleys used to transport components. These have built-in guide rollers, and a special subframe that is mounted inside the washer. The components are loaded on special racks that are already on the trolley, which are then rolled over to the ACE. When the trolley has been positioned in front of the washer, the racks (with the components) are rolled into the machine on the subframe. The racks are constructed for optimal cleaning of the components.

At the end of the washing cycle the components are rinsed for approx. 30 seconds with fresh water of approx. 85° resulting in them being practically dry when they arrive back at the weigher. This self-drying effect is assisted by using a rinse aid.

Specs: Wash area: H 940 x W 1340 x D 800 mm Height of machine with open lid: 2683 mm

(JEACE)

| Category | UTENSIL WASHERS |

| JEROS ACE | The JEROS ACE cleaning system is the most flexible and efficient cleaning system for scale parts. With this system you will achieve a substantial reduction of time you need for the cleaning of scale parts. It speeds up the production output by reducing the product change-over time, cuts labour costs, makes cleaning easier and has a perfect cleaning result. The ACE system is a solution for the increased hygiene regulations in food industry. Due to the rinse temperature, of approx. 85ºC, the components are more or less pasteurized. This is by the laboratory of some customers checked and confirmed. This item is for the customers important. This result is by traditional manual cleaning not possible. |